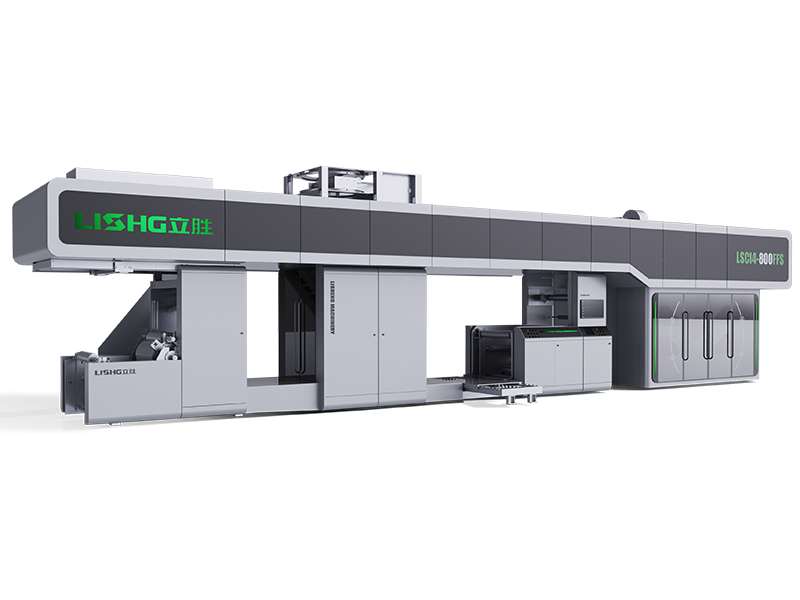

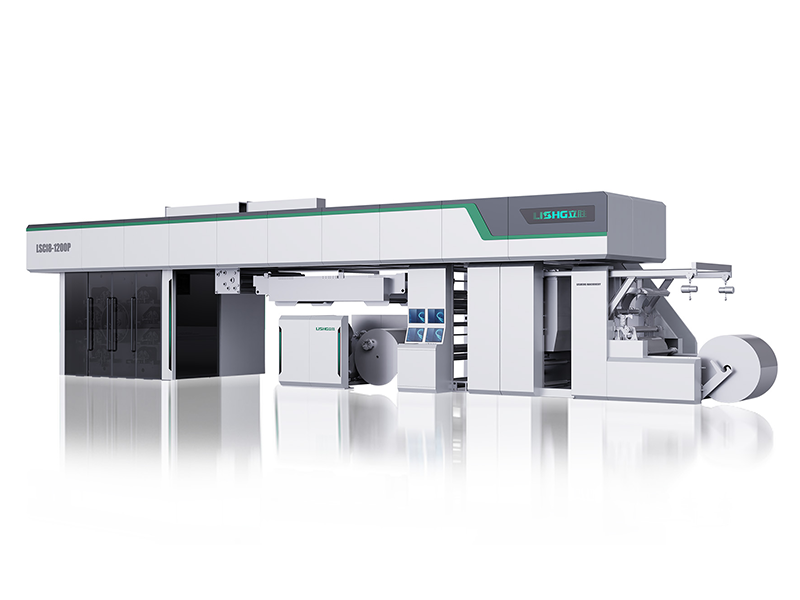

6 Colors Central Impression Flexo Press For Napkin Printing

• Production: 150M/Min (LISHENG Standard) vs 60-80M/Min (Industry Average)

• Calendering: ≤0.02mm (LISHENG Standard) vs ≥0.05mm (Industry Average)

• Color Change: 30min (LISHENG Standard) vs 60-90min (Industry Average)

• Residual Edge: 0mm (LISHENG Standard) vs 3-5mm (Industry Average)

• Blade Life: 20M Cuts (LISHENG Standard) vs 12M Cuts (Industry Average)

Key Features

Technical Parameters

LISHENG MIX5.0 Series Flexo Folding All-in-One Core Value Matrix

Efficiency King, Capacity Overdrive

150M/Min High-Speed Line = 500K Sheets/Day

ROI Period 14 Months

3-Layer Fusion Tech

Patent Calendering Rollers achieve Molecular-Level Bonding

Tear Resistance +40%

Zero-Waste Printing

1200mm Waste Removal Roller + Smart Air Knife = 100% Edge Clearance

Annual Material Saving ¥128K

Color Change Revolution

Modular Ink Trays achieve 6-Color Cleaning in 30min

Annual 154 Labor-Hours Saved

Longevity Components

German Dynamic Balancing Shaft + AI Cutting Algorithm = 20M Precision Cuts

3-Year Saving ¥42K

Agile Delivery

60-Day Standard Delivery

| Parameter | Value/Description |

| Model | MIX-6 |

| Printing Process | Pre-press coating → Printing → Embossing → Folding → Blade cutting |

| Feeding Width | 420 mm |

| Max Printing Width | 420 mm |

| Printing Colors | 6 colors |

| Printing Perimeter | 230 – 420 mm (customizable) |

| Printing Speed | 150 m/min |

| Folding Output | 345 pieces per minute |

| Folding Method | 4/1 and 6/1 folding (using precision folding rollers) |

| Design Requirements | Suitable for single or dual logo designs |

| Material Requirements | Napkin paper with a 3-layer structure; layers are fused through pre-press coating for enhanced strength; each layer weighs 16-18g |

| Key Features | 1. Superior pre-press coating for robust paper structure |

| 2. Optimized arrangement extends blade lifespan | |

| 3. Efficient ink pan cleaning (30 minutes for a 6-color setup) | |

| 4. Precise waste rejection with no unprinted margins (large rollers with air gun assistance) | |

| Delivery Time | Currently 2 months; expected to shorten with increased mass production and parts inventory |

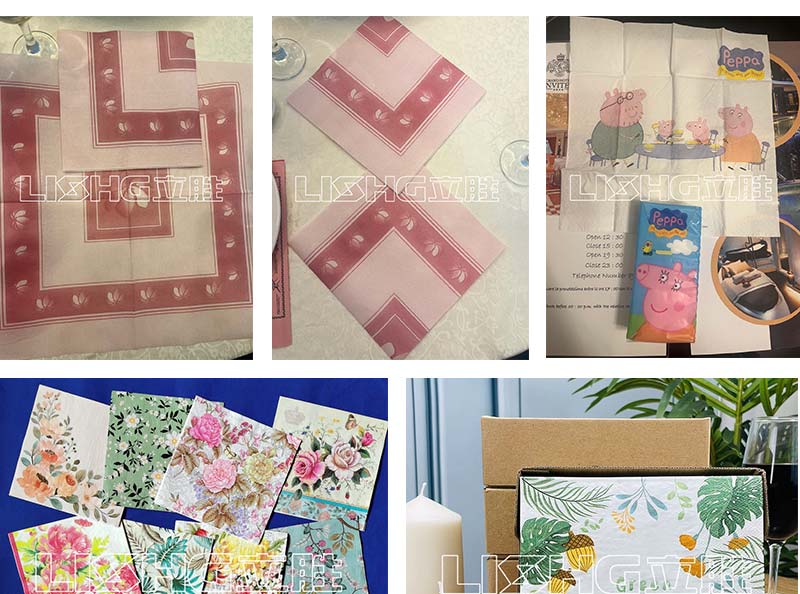

Sample pictures:

More from CI Flexo Printing Machine

Explore Other Series