Why Choose Flexo Printing For Pharmaceutical Packaging?

Importance of Packaging in the Pharmaceutical Industry

Pharmaceutical packaging ensures drug security, product maintenance, and meeting industry standards. It protects medication from being tampered with, harms the shelf life, and communicates vital information which helps consumers.

As the healthcare industry develops, pharma flexo printing has become the most favorable for pharmaceutical packaging due to its showcased benefits, like being cost-efficient and reliable, alongside producing great quality work.

What are the 3 requirement of packaging for pharmaceutical

| Requirement | Description |

|---|---|

| Readability | Packaging must show drug names, dosage, and warnings clearly. Flexo printing gives sharp, clear prints. |

| Safety | Materials must be safe and FDA compliant. Flexo uses safe inks and supports long-term product protection. |

| Sustainability | Packaging should be eco-friendly. Flexo printing uses water-based inks and recyclable materials. |

Readability

Flexo printing covers the drug names, expiration dates, dosage, and warning signs, that have to be incorporated into the packaging. Due to the required small print size, dynamically increasing pharma packaging’s durability and legibility is a must. Text and images are produced in great detail thus Flexo printing is perfect for drug packaging design.

Safety

Designing the medical packaging is safety first. The materials used for the packaging have to be FDA compliant to avoid contamination or degrading the drug. The QbD approach makes sure the packaging support product safety for the entire lifecycle. For drugs, Flexo printing uses special inks and materials that are compliant with pharmaceutical safety standards.

Sustainability

The pharmaceutical sector is gradually adopting a more environmentally friendly approach. This means that all packaging materials must be sustainable. Some companies are minimizing the use of plastics and are using recyclable and even biodegradable materials. Water- based inks and recyclable substrates helps eco-friendly products which flexo printing uses.

What are the 3 Pharmaceutical Packaging Trends?

| Trend | Description |

|---|---|

| Accessibility | Easy-to-read and easy-to-open packaging helps self-medicating patients stay safe and informed. |

| Eco-Friendly Packaging | More use of recyclable, sustainable materials; flexo printing supports this with green technology. |

| Ease of Production | Fast, efficient packaging is needed to meet high demand; flexo printing makes this possible. |

Accessibility

An increase in patients who can self-medicate has grown which requires pharmaceutical packages to be easily readable and accessible. Labels, seals, and other packaging designs which are easy to open promote safety for the user.

Eco-Friendly Packaging

The pharmaceutical industry is also adapting to sustainability as one of the single-use trends. Companies are changing from plastic to recyclable containers, as long as the medication is still protected inside. These efforts are being made with new flexo printing technology which uses sustainable processes.

Ease of Production

Pharmaceutical packaging that is well designed and works efficiently saves time and reinforces quality. There is great demand for medication around the world, which requires fast, scalable, great quality printing. These features are easily supplied with flexo printing unlike other methods.

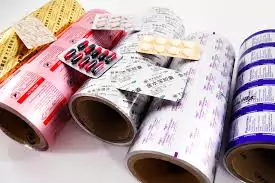

4 Examples of Pharmaceutical Packaging Designs

| Packaging Type | What It’s Used For | How Flexo Printing Helps |

|---|---|---|

| Blister Packs | For tablets and capsules; keeps out air and moisture | Prints clearly and accurately on small blister surfaces |

| Bottle Labels | For medicine bottles; needs to be strong and easy to read | Makes clear, smudge-proof labels that stay on well |

| Patch Packaging | For transdermal patches; must stay safe and clean | Uses safe inks that don’t leak into the patch |

| Foil & Paper Packs | For powder or single-use medicine; needs low-cost and clear printing | Prints well on foil and paper with good quality |

Blister Packs

Drugs like capsules and tablets are best put in blister packs. They provide airtight storage which helps minimize moisture and contamination. Flexo printing is good in precision and this enables pharma packaging printing on blister packs.

Labels for Medication Bottles

Medication bottle labels must be resistant and easy to read. With flexo printing, high-resolution prints do not smear or erode with time because of amazing adhesion and high-quality resolution prints.

Patch Packaging

Contaminated patches need to be packaged properly, which is the case with transdermal patches. Flexo printing makes sure the ink will not leach into the patch, ensuring drug safety and efficiency so that the material does not permeate through the skin.

Foil & Paper Packaging

Powers medications and single dose packs are often packed in foil and paper, and flexo printing delivers cost effective as well as high quality printing for those materials and makes sure that the brand name and prerequisites are visible.

Why Use Flexo for Pharmaceutical Packaging Design?

| Reason | Explanation |

|---|---|

| Cost-effectiveness | Cheaper for large printing jobs compared to methods like gravure |

| Longevity | Plates last a long time, reducing the need for replacements |

| High Quality | Modern flexo gives sharp, clear prints for text and images |

| Fast Speed | Uses roll system to print quickly and in large amounts |

| High Productivity | Quick setup, uses ink efficiently, and reduces waste during printing |

Cost-effectiveness

Flexo printing is the best way to issue high quantities of drawing since it’s less expensive than other types like gravure.

Longevity

Lowering long term costs, flexo printing plates are on the cost effective side while being extremely powerful and durable, so the need to keep replacing them often is eliminated.

Quality

With new advances in technology with pharma flexo printing now providing top of the line flexo prints, text and images displayed have ultra definition, this renews competition with the other expensive printing types.

Speed

An advantage of flexo printing is that it’s able to work on an endless roll system which drastically increases the speed of production and amount per hour, shifting the standard for pharmaceutical manufacturers.

Productivity

Flexo printing increases productivity in pharmaceutical packaging production due to its fast setup times, efficient ink usage, and minimized waste.

Conclusion

The flexibility of pharma packaging has a considerable impact on the healthcare system through drug safety and compliance. Among it’s primary benefits, pharma flexo printing possesses cost effectiveness, high quality and production efficiency while being the ideal choice for pharma product packaging. It is important for industry stakeholders to recognize that implementing flexo printing for drug packaging design will enable them to stay ahead of their rivals while satisfying regulatory requirements and environmental responsibilities as the industry progresses.

References

Pharmaceutical Packaging Trends

Pharmaceutical Packaging Design Tips for Improved Safety