A Comprehensive Technical Review of Flexographic Printing

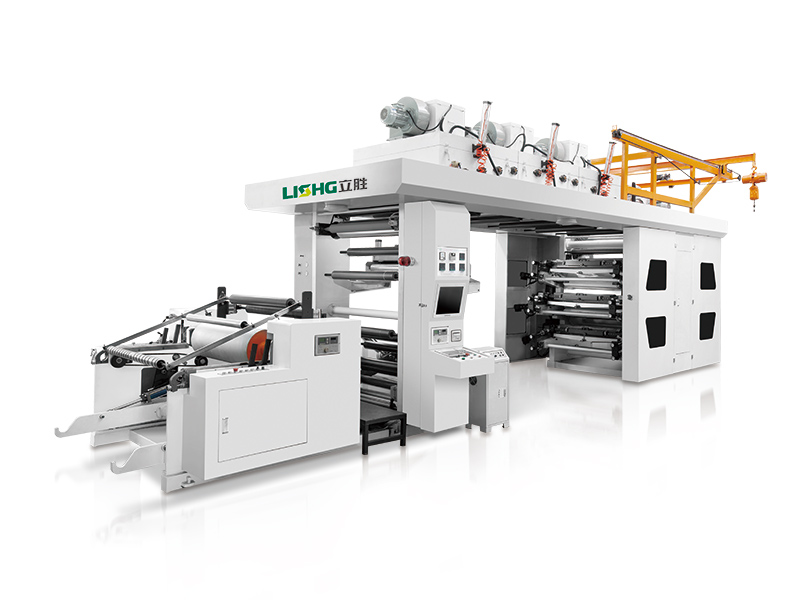

Flexographic printing, often shortened to flexo printing, is a versatile and high-speed printing method that has become the backbone of the modern packaging and labeling industry. Unlike traditional printing methods, flexography’s adaptability allows it to print on a vast range of non-porous and absorbent materials, from flexible films to corrugated cardboard.

This comprehensive guide will provide a technical deep dive into flexographic printing, exploring its process, key components, ink types, applications, and its place in the modern printing landscape.

Understanding the Flexographic Printing Process

At its core, flexographic printing is a form of rotary printing that uses flexible relief plates. The process is a continuous loop, designed for high-volume, rapid production. Here’s a step-by-step breakdown:

- Plate Preparation: The process begins with creating the printing plates. Modern flexo plates are made from a flexible photopolymer material. The image to be printed is raised on the plate’s surface, similar to a rubber stamp. Each color requires its own dedicated plate.

- Ink Transfer: The ink is held in a reservoir and transferred to an anilox roller. This is the heart of the press, as the anilox roller is engraved with a microscopic cell pattern that holds a precise amount of ink.

- Ink Metering: A doctor blade scrapes off any excess ink from the anilox roller, ensuring that only the ink inside the tiny cells is transferred. This is critical for controlling print density and achieving consistent color.

- Image Transfer: The inked anilox roller then rotates, applying a uniform layer of ink to the raised areas of the photopolymer plate.

- Printing: The plate, mounted on a rotating plate cylinder, makes contact with the substrate (the material being printed on), transferring the image.

- Drying/Curing: The printed substrate moves through a drying or curing unit. Depending on the ink type, this could be a hot air dryer for water-based or solvent-based inks, or a UV lamp for UV-curable inks.

- Multi-Color Printing: For multi-color jobs, the substrate passes through multiple printing stations, each with its own plate and ink, to build the complete image.

In-Depth Analysis of Flexo Printing Components

The quality and efficiency of a flexo press depend on the seamless interaction of its core components.

| Component | Function | Key Characteristics |

| Flexo Printing Plates | Transfers the raised image to the substrate. | Material: Photopolymer (replaces traditional rubber). <br> Benefits: Superior durability, holds finer details. <br> Process: Imaged by laser to create a raised surface. |

| Anilox Rollers | Precisely meters and delivers ink to the printing plate. | Material: Ceramic-coated steel/aluminum with microscopic cells. <br> Key Parameters: Line Screen (LPI) for detail, Cell Volume (BCM) for ink density, and Cell Geometry for ink release. |

| Doctor Blades | Scrapes off excess ink from the anilox roller. | Material: Thin, flexible blade. <br> System: Often part of an enclosed chamber system to maintain consistent ink volume and prevent drying. |

| Inking Systems | Supplies ink to the anilox roller. | Most Common: Enclosed chamber doctor blade system. <br> Benefits: Provides superior control over ink viscosity, reduces solvent evaporation, and minimizes waste. |

Flexo Printing Plates

Traditionally made from rubber, modern flexo plates are now predominantly made from photopolymer. This material offers superior durability, dimensional stability, and the ability to hold finer details, which is essential for high-quality graphics and halftones. The plates are imaged using a laser, which cures the photopolymer and leaves the image area in relief.

Anilox Rollers

The anilox roller is arguably the most critical component in controlling ink delivery. It is a hardened cylinder, typically made of steel or aluminum with a ceramic coating, that is laser-engraved with millions of microscopic cells. The key parameters of an anilox roller are:

- Line Screen (LPI): The number of cells per linear inch. A higher line screen results in finer details and smoother gradients.

- Cell Volume (BCM): The volume of ink each cell can hold. This directly controls the ink film thickness and color density on the final print.

- Cell Geometry: The shape of the cells (e.g., hexagonal, quadrangular) which affects ink release and transfer efficiency.

Choosing the right anilox roller for a specific job is vital for achieving the desired print quality.

Doctor Blades

A doctor blade is a thin, flexible blade that rests against the anilox roller. Its sole purpose is to precisely scrape away excess ink from the roller’s surface, leaving only the required amount of ink within the engraved cells. The design of the doctor blade system, particularly an enclosed chamber system, prevents ink from drying out and maintains a consistent ink volume.

Inking Systems

Flexo presses use various inking systems to deliver ink to the anilox roller. The most common is the enclosed chamber doctor blade system. This system encloses the ink and the anilox roller in a sealed chamber, which is a significant improvement over older open-tray systems. It provides superior control over ink viscosity and consistency, reduces solvent evaporation, and minimizes ink waste.

Types of Flexographic Inks

The versatility of flexography is largely due to its ability to work with a range of fast-drying, low-viscosity inks. The choice of ink is determined by the substrate, the desired finish, and environmental regulations.

| Ink Type | Key Characteristics | Advantages | Best for |

| UV-Curable | Cures instantly with UV light; no solvents. | Exceptional durability, high gloss, excellent resistance, no VOCs. | Non-porous materials (plastic films, high-end labels). |

| Water-Based | Water is the primary solvent. | Environmentally safe, cost-effective, good color vibrancy, very low VOCs. | Porous materials (paper, cardboard). |

| Solvent-Based | Uses volatile solvents like alcohol. | Excellent adhesion, high print speeds, strong resistance to chemicals. | Non-porous materials (flexible films, plastic bags). |

UV-Curable Inks

UV-curable inks do not contain solvents or water. Instead, they are composed of monomers and oligomers that solidify instantly when exposed to a specific spectrum of ultraviolet (UV) light.

- Advantages: Exceptional durability, high gloss, abrasion and chemical resistance, and no volatile organic compounds (VOCs).

- Best for: Non-porous materials like plastic films, flexible packaging, and high-end labels.

Water-Based Inks

Water-based inks use water as their primary solvent. They are considered the most environmentally friendly option due to their very low VOC content.

- Advantages: Environmentally safe, cost-effective, and provide good color vibrancy.

- Best for: Porous, absorbent substrates such as paper, paperboard, and corrugated cardboard.

Solvent-Based Inks

Solvent-based inks use volatile solvents like alcohol or esters to carry the colorants. They dry quickly through evaporation.

- Advantages: Excellent adhesion to non-porous surfaces, high print speeds, and strong resistance to water and chemicals.

- Best for: Flexible films, plastic bags, and other non-porous packaging materials where strong adhesion is required.

Print Quality Control and Registration Accuracy

High-quality flexo printing requires meticulous attention to detail. Print registration accuracy—ensuring that each color plate aligns perfectly—is paramount for crisp, clean images. Modern flexo presses feature advanced digital controls and camera systems to monitor and automatically adjust plate positions in real time.

Another key factor is dot gain. Because flexo plates are flexible and inks are fluid, the ink dots can spread on the substrate, making the printed image appear darker than intended. Prepress adjustments, such as creating smaller dots on the plate, are made to compensate for this effect.

Applications of Flexographic Printing

Flexo’s adaptability makes it the ideal solution for a vast number of applications.

- Flexible Packaging Printing: Used for printing on a variety of flexible substrates like plastic pouches, wraps, and bags for snacks, coffee, and frozen foods.

- Label Printing: The go-to method for producing a wide range of labels, from simple product labels to complex multi-layered labels for food, beverage, and medical products.

- Corrugated Board Printing: The robust nature of flexo makes it perfect for printing directly onto corrugated cardboard boxes and displays.

- Film Printing: Used extensively for printing on plastic films for shrink sleeves, laminations, and other packaging materials.

- Food Packaging Printing: Flexography is a dominant force in food packaging due to the use of food-safe inks and its ability to print on flexible films, foils, and paper.

Flexographic Printing vs. Offset Printing

While both are major commercial printing methods, they operate on fundamentally different principles.

- Plates: Flexo uses flexible, raised-image photopolymer plates, while offset uses rigid, flat metal plates where the image is non-raised.

- Ink Transfer: Flexo is a direct printing process (plate to substrate), whereas offset is an indirect process (plate to blanket cylinder to substrate).

- Substrate Versatility: Flexo is far more versatile, capable of printing on a wide variety of porous and non-porous materials, including films, foils, and plastics. Offset is primarily used for flat, porous materials like paper and cardstock.

- Cost & Speed: Flexo is more cost-effective for very long runs and offers higher printing speeds, making it ideal for the high-volume packaging industry. Offset is typically preferred for shorter runs where high-fidelity, fine-detail graphics on paper are required, such as magazines and brochures.

Innovations and Future Trends in Flexographic Printing

The flexo industry is continuously evolving. Key innovations include:

- Expanded Gamut (EG) Printing: Using a fixed set of inks (typically CMYK plus orange, green, and violet) to reproduce a wider range of colors, reducing the need for expensive spot color inks and minimizing press downtime.

- Advanced Digital Platemaking: New platemaking technologies are allowing for higher-resolution images and more consistent dot structures, pushing the boundaries of flexo print quality.

- Automation and Digital Integration: Modern presses feature sophisticated automation for job changeovers, color matching, and quality control, which significantly boosts efficiency and reduces waste.

- Sustainability: A growing focus on using water-based and UV-LED inks to reduce VOC emissions and energy consumption, aligning with a global push for more sustainable manufacturing.

Conclusion

Flexographic printing is more than just a printing method; it is an essential technology that powers the global packaging and labeling supply chain. Its ability to combine speed, efficiency, and a broad range of applications makes it the top choice for businesses requiring high-volume, cost-effective, and high-quality printed packaging. As innovations continue to improve print quality and sustainability, flexography will remain a cornerstone of the printing world for years to come.

Want to learn more about how our state-of-the-art flexo printing machines can revolutionize your production process? Visit our website or contact us for a consultation!