What is the Difference Between CI Flexo and Stack Flexo? 8 Key Differences

In the fast-paced world of packaging and printing, flexographic printing—commonly known as flexo printing—has emerged as a preferred technology for high-speed, high-volume production. Among the various types of flexo presses, two dominate the landscape: the CI flexo printing machine and the stack flexo printing machine.

This article explores the key differences between CI flexo and stack flexo printing machines, helping manufacturers, converters, and packaging professionals choose the most suitable solution for their needs.

What is Flexo Printing and Its Role in Packaging?

Flexo printing is a rotary printing process that uses flexible relief plates and quick-drying inks to print on a variety of substrates. It’s widely used in the packaging industry for applications such as flexible packaging, labels, cartons, and corrugated boxes. Thanks to its versatility, speed, and cost-efficiency, flexo printing remains a go-to technology for many printing businesses worldwide.

Learn More: 4 Main Types Of Flexo Printing Machine

What is a CI Flexo Printing Machine?

A CI flexo printing machine features a central impression cylinder around which all color stations are arranged. This large drum holds the substrate in place as it moves through each color station, ensuring precise registration and minimal vibration.

CI flexo presses are known for their:

-

High print quality and tight color registration

-

Compact and stable design

-

Speed and suitability for flexible packaging materials, such as plastic films

They are often the machine of choice in industries requiring premium packaging, such as food, beverage, and personal care.

Want to find a reliable CI flexo printing machine manufacturer?

Learn More: Best 6 Ci Flexo Printing Machine Manufacturer

Learn More: Top Ci Flexo Printing Machine Manufacturer In India

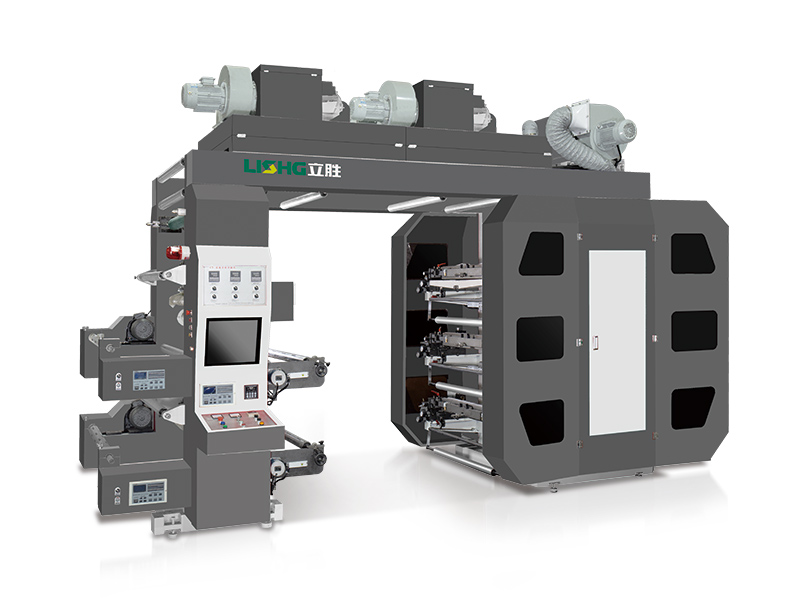

What is a Stack Flexo Printing Machine?

A stack flexo printing machine uses a vertical or horizontal stacked configuration, where each color station is arranged one above or beside the other. Each station has its own impression cylinder.

Stack type flexo printing machines are valued for their:

-

Versatile substrate handling (paper, film, foil, cardboard)

-

Simpler structure and lower cost

-

Good accessibility for setup and cleaning

These machines are commonly used for corrugated packaging, paper bags, and general-purpose printing where precision is less critical.

What is the Difference Between CI Flexo and Stack Flexo?

Let’s break down the 8 key differences between CI flexo and stack flexo printing machines:

| Category | CI Flexo | Stack Flexo |

|---|---|---|

| Structure | Central drum, compact layout | Stacked units, vertical/horizontal setup |

| Printing Materials | Best for flexible films | Handles paper, film, foil, cardboard |

| Print Quality | High registration accuracy | Good, but less precise for complex jobs |

| Applications | Shrink sleeves, pouches, labels | Paper bags, corrugated boxes |

| Production Speed | Very high (400+ m/min) | Moderate (200–300 m/min) |

| Space Needed | Compact floor space | Needs more vertical space |

| Operation & Maintenance | More complex, ideal for long runs | Simpler, better for short runs |

| Cost | Higher initial cost, efficient long-term | Lower cost, great for smaller-scale production |

Structure

-

CI Flexo: Compact design with a central impression drum surrounded by all print stations.

-

Stack Flexo: Modular and vertically or horizontally stacked units, each with its own impression roller.

Printing Materials

-

CI Flexo: Best suited for thin, stretchable materials like plastic films and flexible packaging.

-

Stack Flexo: Handles a broader range of substrates including paper, film, foil, and cardboard.

Print Quality

-

CI Flexo: Offers superior registration accuracy, ideal for high-end, detailed prints.

-

Stack Flexo: Good for general-purpose printing but may struggle with complex multi-color registration.

Applications

-

CI Flexo: Used in food packaging, shrink sleeves, pouches, and high-quality label printing.

-

Stack Flexo: Common in paper bags, corrugated boxes, and jobs requiring duplex printing.

Production Speed

-

CI Flexo: Capable of very high speeds, often exceeding 400 m/min.

-

Stack Flexo: Generally slower, around 200–300 m/min, depending on setup.

Space Needed

-

CI Flexo: Requires less floor space thanks to its compact footprint.

-

Stack Flexo: Requires more vertical space, making it suitable for facilities with high ceilings.

Operation & Maintenance

-

CI Flexo: More complex, with higher maintenance demands but better suited for long print runs.

-

Stack Flexo: Easier to operate and maintain, ideal for shorter or mixed-batch jobs.

Cost

-

CI Flexo: Higher upfront investment, but more efficient in the long term for high-volume work.

-

Stack Flexo: More cost-effective for smaller operations with lower capital investment.

Learn More: Ci Flexo Vs Inline Flexo

How to Choose Between CI Flexo and Stack Flexo?

Here’s a quick decision guide:

Choose CI Flexo if:

-

You need top-tier print quality

-

You work with flexible films and plastics

-

You run large-scale, high-speed production

-

Tight color registration is critical

Choose Stack Flexo if:

-

You print on paper, cardboard, or mixed substrates

-

You value lower equipment cost and easy maintenance

-

You run short to medium print jobs

-

You need flexibility in design and color options

Always consider factors such as substrate type, job volume, available space, and budget before making your final choice.

Conclusion

Understanding the difference between CI flexo and stack flexo printing machines is crucial for any business in the packaging and printing industry. Each press type offers distinct advantages that cater to different production needs and business models.

Whether you prioritize high-speed precision or cost-effective flexibility, choosing the right flexo press will directly impact your productivity, print quality, and bottom line.

For expert advice on selecting the best CI flexo presses or stack type flexo printing machines, feel free to contact our team. We’re here to help you make an informed, confident decision.