The Hidden Disadvantages of a Gearless Flexo Printing Press You Must Know Before Buying

Introducción

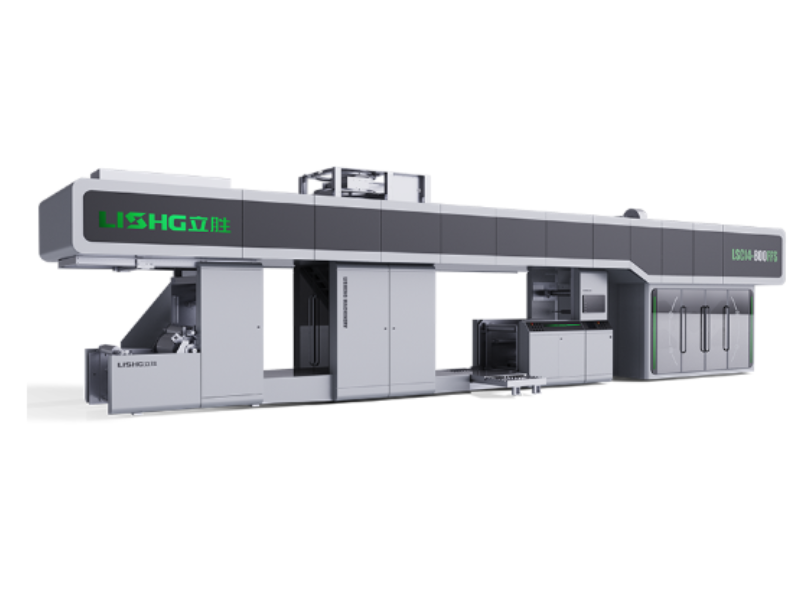

If you are looking to upgrade your flexo printing press, you have probably noticed how popular gearless technology has become in the packaging industry. A Prensa flexográfica sin engranajes promises higher precision, smoother running, faster setup, and better print quality. It sounds perfect. But in real production, no machine is perfect. Every advanced technology comes with its own limitations, and gearless flexo presses are no exception. As a buyer, especially in South America, Vietnam, North Africa, the Middle East, or Hong Kong, your decision should not be based only on “how advanced” the machine is, but on whether it truly fits your production scale, technical team, power conditions, and budget. In this article, you will clearly understand the real disadvantages, hidden costs, and operational challenges of a gearless flexographic press, while also seeing how trusted manufacturers like Lisheng help you reduce these risks through smart design and professional support.

Understanding Gearless Technology in a Flexo Printing Press

A traditional flexographic printing press uses mechanical gears to connect each printing unit. In a gearless system, each unit is driven independently by servo motors and synchronized digitally. This eliminates gear backlash and vibration, resulting in higher registration accuracy, lower noise, faster job changes, and more stable long-run performance. However, the moment you remove mechanical simplicity, you increase reliance on electronics, software, and skilled operation. That is where most disadvantages come from.

Disadvantages of Gearless Flexo Printing Press

Although a Prensa flexográfica sin engranajes is known for its high precision and advanced automation, it is not always the perfect solution for every printing factory. Before investing, you should clearly understand its disadvantages from technical, financial, and operational perspectives. This will help you choose the right flexo printing press based on your real production needs.

High Initial Investment Cost

The biggest disadvantage of a Prensa flexográfica sin engranajes is its high purchase price. Compared with a traditional flexographic printing press, gearless systems require advanced servo motors, PLC controllers, digital synchronization systems, and precision electronic components.

| Machine Type | Average Price Range |

|---|---|

| Traditional flexo printing machine | USD 40,000 – 90,000 |

| Gearless flexographic printing machine | USD 120,000 – 300,000+ |

This cost gap makes gearless machines less attractive for:

-

Small printing factories

-

Start-up businesses

-

Low-margin packaging production

If your production mainly involves simple designs or short runs, a traditional prensa flexográfica or a 4 color flexo printing machine may offer better ROI.

High investment also means:

-

Longer payback period

-

Higher financial pressure

-

Greater dependence on stable order volume

Higher Maintenance Cost of Electronic Components

In a traditional flexographic press, most maintenance is mechanical. In a gearless system, maintenance is mainly electronic.

Common electronic components that may need replacement:

-

Servo motors

-

Servo drives

-

Encoders

-

Control boards

-

PLC modules

These parts are:

-

More expensive

-

More sensitive to environment

-

Harder to repair locally

| Component Type | Flexografía tradicional | Flexografía sin engranajes |

|---|---|---|

| Spare parts cost | Bajo | Alto |

| Availability | Easy | Brand-dependent |

| Repair complexity | Simple | Complex |

For factories in South America, North Africa, or the Middle East, spare part logistics can increase downtime and operating costs.

Strong Dependence on Skilled Operators and Engineers

A Prensa flexográfica sin engranajes requires higher technical knowledge. Operators must understand:

-

Servo motor synchronization

-

Touchscreen control systems

-

Error code diagnosis

-

Software parameter settings

Without proper training:

-

Setup time increases

-

Risk of operational errors rises

-

Machine efficiency drops

This makes gearless technology less suitable for factories that:

-

Lack automation engineers

-

Have high staff turnover

-

Do not invest in training

In contrast, a traditional flexo printing press is more forgiving and easier for basic operators.

High Sensitivity to Power Supply Stability

Gearless machines rely completely on stable electrical power. Power quality problems can lead to:

-

Servo misalignment

-

Control system failure

-

Frequent machine alarms

-

Damage to electronic components

This is a serious issue in regions with:

-

Voltage fluctuations

-

Power outages

-

Weak industrial power grids

| Power Condition | Flexografía tradicional | Flexografía sin engranajes |

|---|---|---|

| Power tolerance | Alto | Bajo |

| Extra equipment needed | Rare | Stabilizers / UPS |

You may need:

-

Voltage stabilizers

-

Surge protectors

-

Backup generators

These increase the hidden cost of a máquina de impresión flexográfica investment.

More Complex Troubleshooting and Longer Downtime

When a traditional prensa flexográfica stops, the fault is often mechanical and visible. When a Prensa flexográfica sin engranajes stops, the problem may be:

-

Software-related

-

Communication error

-

Servo synchronization fault

-

Sensor failure

This makes troubleshooting:

-

More technical

-

More time-consuming

-

Highly dependent on manufacturer support

| Factor | Flexografía tradicional | Flexografía sin engranajes |

|---|---|---|

| Fault detection | Easy | Complex |

| Repair speed | Rápido | Más lento |

| Technical dependency | Bajo | Alto |

If remote technical support is slow, downtime can be costly.

Higher Cost and Limited Choice of Spare Parts

Electronic spare parts are:

-

More expensive

-

Often proprietary

-

Must be original or compatible

This creates:

-

Higher inventory cost

-

Dependence on original manufacturer

-

Longer waiting time for overseas shipments

For international buyers, this is a serious operational risk.

Risk of Software and Control System Failure

A Prensa flexográfica sin engranajes operates on complex control software. Software-related risks include:

-

System crashes

-

Program errors

-

Compatibility issues after updates

-

Data loss

You must:

-

Backup control programs regularly

-

Maintain software versions

-

Train technicians in system recovery

This is a completely new responsibility compared with traditional máquinas de impresión flexográfica.

Not Cost-Effective for Low-Volume Production

Gearless technology is designed for:

-

High-speed printing

-

High-precision registration

-

Long production runs

If your factory focuses on:

-

Short orders

-

Simple packaging

-

Small batch production

Then a traditional flexo printing press o 4 color flexo printing machine will often be more profitable.

| Production Type | Best Choice |

|---|---|

| High-end packaging | Gearless flexo |

| Simple packaging | Traditional flexo |

| Pequeños lotes | Traditional flexo |

| Large volume | Gearless flexo |

Higher System Complexity and Installation Difficulty

A Prensa flexográfica sin engranajes consists of:

-

Multiple servo motors

-

High-speed communication networks

-

Advanced motion control systems

-

Safety interlock systems

This makes:

-

Installation longer

-

Commissioning more complex

-

Training period extended

The initial startup phase requires strong technical support.

High Dependence on the Manufacturer

Because of proprietary electronics and software, you rely heavily on your supplier for:

-

Spare parts

-

Software updates

-

Technical troubleshooting

-

System upgrades

This means:

-

Supplier reliability is critical

-

Brand selection becomes strategic

-

Long-term service capability matters more than price

Choosing an experienced supplier like Lisheng flexo printing press manufacturers reduces this risk significantly.

Gearless Flexo Printing Press vs Traditional Flexo Printing Press

| Artículo | Prensa flexográfica sin engranajes | Traditional Flexographic Printing Press |

|---|---|---|

| Initial investment | Very high | Moderate to low |

| Maintenance type | Electronic-based | Mechanical-based |

| Spare parts cost | Alto | Bajo |

| Operator skill requirement | Alto | Medio |

| Power stability requirement | Very high | Bajo |

| Troubleshooting difficulty | Complex | Simple |

| Print accuracy | Excelente | Bien |

| Setup time | Very fast | Más lento |

| Lo mejor para | High-end, high-volume production | Small to medium production |

Real Buyer Case: South America Packaging Converter

A packaging company in Brazil was using a traditional máquina de impresión flexográfica for snack packaging and basic label production. Their print quality was acceptable, but registration issues and material waste were becoming expensive. They decided to invest in a Lisheng Gearless Flexo Printing Press with 6 colors.

At the beginning, they faced two main challenges:

Higher electricity requirements and unstable power supply

Operators unfamiliar with servo-driven control systems

They installed voltage stabilizers and accepted remote training from Lisheng engineers. Within three months, they reported:

Waste reduction by nearly 25%

Faster job changeover by 40%

More stable color registration

Higher customer satisfaction

However, they also admitted that maintenance costs increased and technical dependency on the supplier became stronger. For them, the disadvantages were real, but acceptable because production quality improved significantly.

Real Buyer Case: Middle East Flexible Packaging Producer

A medium-sized converter in Saudi Arabia focused on short-run packaging and promotional labels. They purchased a high-speed Prensa flexográfica sin engranajes expecting better productivity.

After six months, their feedback was honest:

The machine performance was excellent

Print quality exceeded expectations

But their production volume was not high enough to fully utilize its capacity

They realized that a standard prensa flexográfica or a 4 color flexo printing machine could have met most of their needs with much lower cost. This case clearly shows that the biggest disadvantage of a gearless system is not technical, but strategic: choosing a machine that is more powerful than your real production demand.

How Lisheng Reduces the Disadvantages of Gearless Technology

When you invest in a Prensa flexográfica sin engranajes, the machine itself is only part of the equation. The real value lies in how well the manufacturer helps you control its disadvantages. Lisheng focuses on making gearless technology practical, stable, and cost-effective for global buyers of flexo printing press systems.

Using International Standard Servo Systems to Lower Maintenance Risk

Lisheng Gearless Flexo Printing Press machines are built with internationally recognized servo motors, servo drives, and PLC control systems. This brings two major benefits:

-

Spare parts are easier to source worldwide

-

Replacement costs are more controllable

Unlike proprietary electronic systems, standardized components mean you are not locked into a single supplier. This significantly reduces long-term maintenance risk for your máquina de impresión flexográfica.

Simplified Control System for Faster Operator Learning

One of the biggest disadvantages of a flexographic press is its learning curve. Lisheng designs its control interface to be intuitive and production-oriented.

Key features include:

-

Visual job memory management

-

One-touch parameter recall

-

Clear alarm display with solutions

-

Multi-language support

This reduces:

-

Operator training time

-

Human errors

-

Setup delays

For factories upgrading from traditional flexo printing press machines, this design makes the transition smoother and safer.

Remote Technical Support to Reduce Downtime

Downtime is the hidden cost of every máquina de impresión flexográfica. Lisheng provides:

-

Online video diagnostics

-

Remote PLC troubleshooting

-

Software parameter guidance

This allows most issues to be solved without waiting for on-site service, which is especially important for customers in South America, Vietnam, North Africa, and the Middle East.

Power Protection Design for Unstable Electricity Regions

Lisheng understands that many markets have unstable power conditions. Every Lisheng Gearless Flexo Printing Press is designed to support:

-

Voltage stabilizers

-

Surge protectors

-

UPS backup systems

This protects sensitive electronic components and ensures stable production even in challenging electrical environments.

| Power Issue | Lisheng Solution |

|---|---|

| Voltage fluctuation | Built-in protection interface |

| Power outage | UPS compatibility |

| Power surge | Surge suppressor integration |

Modular Design to Control Investment Cost

Instead of forcing buyers to purchase full automation, Lisheng offers modular configurations:

-

Basic gearless control system

-

Semi-automatic registration

-

Full automatic registration

This allows you to choose the most cost-effective configuration for your flexo printing press, reducing unnecessary investment.

Standardized Spare Parts System to Lower Inventory Pressure

Lisheng uses a standardized spare parts structure so that:

-

One servo type can fit multiple machine models

-

PLC modules are interchangeable

-

Electrical components are globally available

This reduces spare parts inventory cost and shortens repair time for your flexographic printing press.

Export-Oriented Design for Global Markets

El Lisheng flexo printing press is designed specifically for international markets, with:

-

CE certification options

-

English technical documentation

-

Remote training support

-

Export-standard electrical systems

This ensures smooth installation and operation worldwide.

Training System for Operators and Engineers

Lisheng provides:

-

Online operation training

-

Maintenance manuals

-

Troubleshooting guides

-

Real-time video support

This builds your internal technical capability and reduces reliance on external service providers.

Long-Term Service Strategy for Gearless Systems

Unlike suppliers who only sell machines, Lisheng focuses on long-term cooperation:

-

Stable software versions

-

Continuous technical updates

-

Spare part supply guarantees

This is critical for high-end Prensa flexográfica sin engranajes users who need stable operation for years.

Balanced Design Between Performance and Cost

Lisheng does not pursue unnecessary complexity. Every Lisheng Gearless Flexo Printing Press is engineered to balance:

-

Performance

-

Stability

-

Cost control

This makes Lisheng machines especially suitable for developing and emerging markets.

Conclusión

A Prensa flexográfica sin engranajes offers unmatched accuracy, speed, and print consistency, but its disadvantages are clear: higher investment, stronger dependence on stable power, greater technical complexity, and higher electronic maintenance costs. These challenges do not mean the technology is unsuitable; they simply mean it is designed for buyers who are ready to move toward automation and precision manufacturing.

If you want to reduce waste, improve efficiency, and build a high-end packaging production line, the Lisheng Gearless Flexo Printing Press is a reliable solution built for international markets. Contact Lisheng today to get professional advice, customized machine configurations, and a quotation that matches your real production needs. The right machine is not the most expensive one, but the one that grows with your business.

Preguntas frecuentes

Q1: Is a Gearless Flexo Printing Press suitable for small factories?

A gearless system can work for small factories, but only if you have stable power supply and trained operators. Otherwise, a traditional flexo printing press or a 4 color flexo printing machine may be more cost-effective.

Q2: Why choose Lisheng Gearless Flexo Printing Press instead of other brands?

Lisheng offers standardized servo components, simple control systems, strong export experience, and fast technical support, which significantly reduces the disadvantages of gearless technology.

Q3: What is the biggest hidden cost of a Gearless Flexo Printing Press?

Power stabilization equipment, electronic spare parts, and operator training are often underestimated but are essential for stable operation.

Q4: Can Lisheng flexo printing press machines work in unstable power regions?

Yes. Lisheng designs its machines to support voltage stabilizers and surge protection systems, making them suitable for South America, Africa, and the Middle East.

Q5: Is gearless technology better than traditional flexography in all cases?

No. Gearless technology is better for high-end, high-volume, and high-precision production. Traditional máquinas de impresión flexográfica are still ideal for basic packaging and lower budgets.