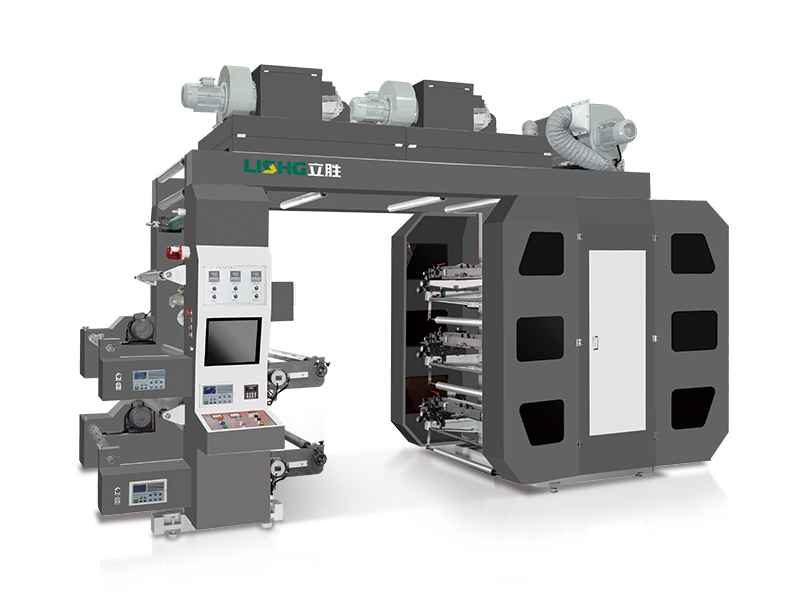

4 6 Color Central Drum Flexo Press For PP Woven Bag Printing

Product Specifications:

Suitable Material: Paper, Films, Non-Woven, Fabric, Foils

Max Width Of Material: 1200mm

Max Printing Width: 1160mm

Print Color: 4 6 colors

Max Printing Speed: 250m/min

Machine Weight: 8500kg

Machine Dimension: 9.7*3.7*3.2M(L*W*H)

Machine Power: 380V,3PH,50hz

Key Features

Technical Parameters

Main parameter:

| Model | YTC-4 6 color |

| Material feeding width | 600mm 800mm 1000mm 1200mm |

| Max Printing Width | 560mm 760mm 960mm 1160mm |

| Colors | 4 6 colors |

| Material | Film |

| Thickness of plate | 1.14mm.1.7mm 2.28mm.2.84mm. 3.94mm Customized is available |

| Printing length | Standard is 400mm, Customized is available from300-1000mm |

| Maximum machinespeed | 150m/min |

| Printing speed | 120m/min |

| Register precision | longitudinal registration±0.2mm Transversal registration±0.2mm |

| Structure type | Central impression(central drum) |

| Gear module | 1.5mm |

| Heating method | Electricity heating |

| Max. oven temp. | Max. 80℃(room temp. 20℃) |

| Unwinder/rewinder paper | core 3" |

| Max.unwinder/rewinder dia. | 1200mm |

| Suitable Ink | Water based ink / Solvent ink |

Characteristics:

1.Central impression type printing machine with better color registration. Due to the big drum, the printed material is supported by the big drum, and greatly improving color registration, especially with extensible materials.

2.All colors printing station drived by the central drum, Less transmission errors because of less gear transmission, increase the registration precision.

3.Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

4.The machine is equipped with blower and heater; and the heater employed central temperature control system, automatic temperature controller, and separated heat source.

5.The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6.Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7.Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance, beating small, achieves finally perfect printing effect.

8.Accurate printing effect achieved by special gear transmission device.

9.The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

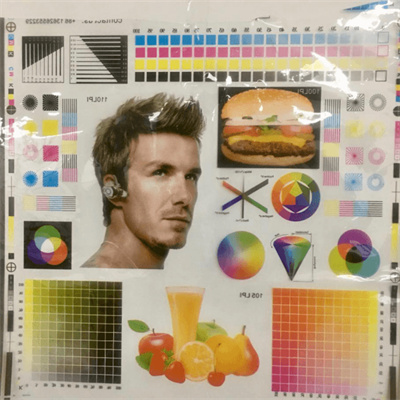

Paper:

Film:

More from CI Flexo Printing Machine

Explore Other Series