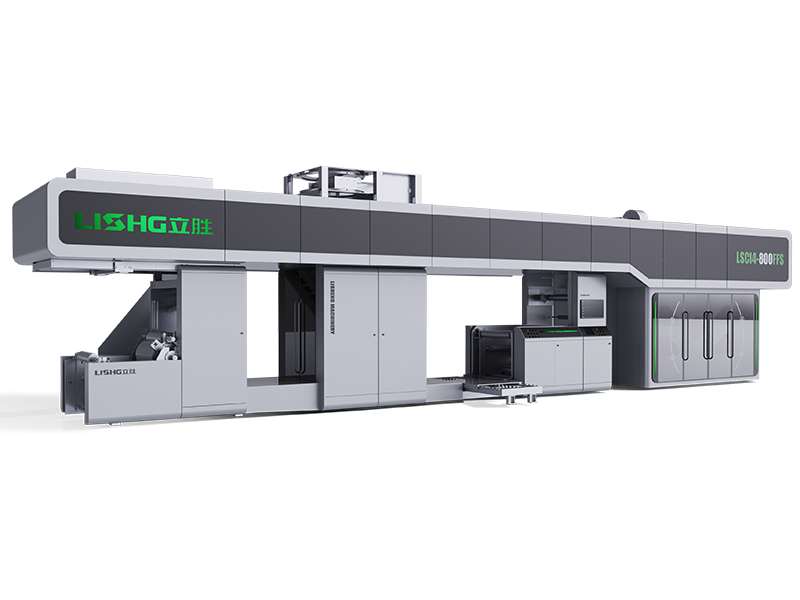

Honor Servo Stack Flexo Printing Machine

Product Application:

Number of printing units 6-colors

Printing width 1160 mm

Print repeat 300 – 1000 mm

Mechanical speed max. 200 m/min

Key Features

Technical Parameters

Machine core components:

1.drive servo motor

2.printing unit servo motor

3.active unwinding+rewinding servo motor

4.traction servo motor

5. chamber doctor blade

6. PLC control system

7. video inspection static monitoring system

8. ink circulation system

| Raw material | Thickness | |

| LDPE | 50 µm | 250 µm |

| HDPE | 50 µm | 150 µm |

| PET | 50 µm | 75 µm |

| PP | 50µm | 245 µm |

| Paper | 40 g/m2 | 95 g/m2 |

| (Depending on the raw material type and the web tension range mentioned above)Printing Technology: Printing is done using water-based and alcohol-soluble, environmentally friendly inks and photosensitive resin plates. | ||

Technical Specification:

| Model | Honor series |

| Material Feeding Width | 1200mm |

| Max Printing Width | 1160mm |

| Colors | 6colors |

| Material | PE PET BOPP PVC |

| Thickness of plate | 1.14mm.1.7mm 2.28mm.2.84mm. 3.94mm Customized is available |

| Printing length | Standard is 400mm,Customized is available from 300-1000mm |

| Max Machine speed | 220m/min |

| Max Printing speed | 200m/min(Depends on material thickness and printing pattern) |

| Register precision | ±0.2mm |

| Heating method | Electricity heating |

| Max. unwind diameter | 800mm |

| Max. rewind diameter | 800mm |

| Part 1 Unwinding And Rewinding Unit | |

|  |

| 1.This machine adopt active rewinding and unwinding, controlled by servo motors. The rewinder features a guide-type pressure roller design for smoother material collection. Combined with a roll diameter detection system, this system provides greater accuracy and stability, while also minimizing material stretching during the printing process, ensuring high yield rates. 2.Tension Control: Utilizes servo swing arm control (low-friction cylinder position detection and precision pressure regulating valve control). Automatic alarms and shutdowns are activated when the roll diameter reaches the set value. 3.The pneumatic shaft has a loading outer diameter of 3 inches and is clamped by a two-head cylinder disengagement system. 4.An automatic dual-roller process correction system is installed before printing, with adjustable left andright translation. | |

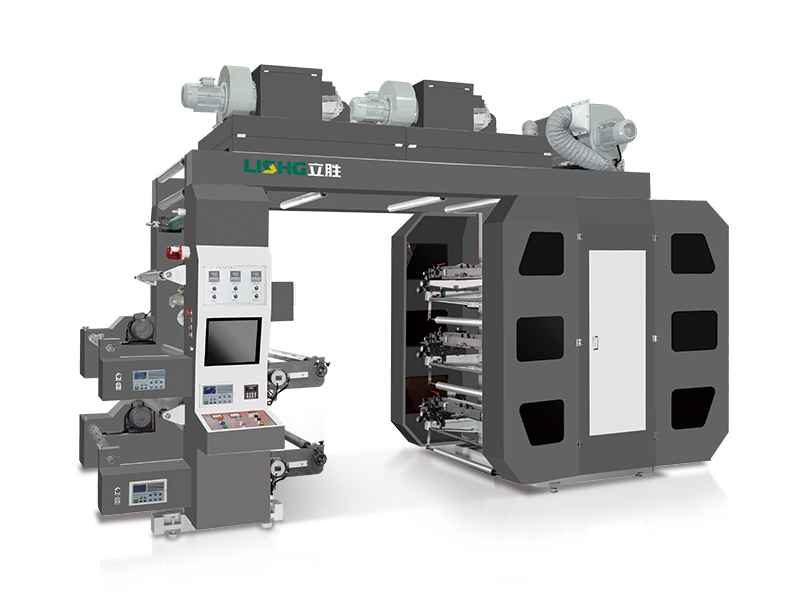

| Part 2 Printing Unit | |

|  |

| 1.Full-width double-sided Printing Capability: Supports multiple printing modes, including 6+0 (single-sided), 5+1, 4+2,3+3 (double-sided printing). 2.The printing group adopts servo motor control system to quickly achieve 360-degree color registration, This provides more convenient operation and more stable printing, eliminating tedious manual operations. 3.Cylinder Specifications: Printing Circumference 300-1000mm. 4.Ceramic Anilox Roller Specifications: Screen Screen Range 80-1000 LPI. | |

| Part 3 Drying Unit | |

|  |

| 1.Drying Method: Electric heating. Maximum oven temperature: 80°C (room temperature: 20°C). 2.Top Drying System: Equipped with a return air drying circulation system for fast drying. 3.Drying System: Drying modules are installed between each color room of the printing press to improve drying efficiency. 4.Applicable to: Applicable to the entire machine drying oven and the drying units between each color room. | |

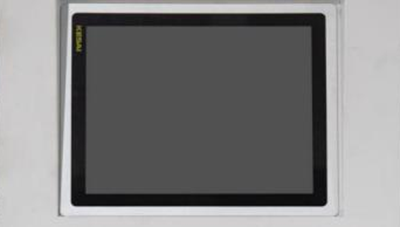

| Part 4 Image static monitoring system | |

|  |

| 1.The static image monitoring system video inspector has a magnification of 3-30 (area magnification), displaying full screen. The image capture interval is automatically determined based on the position signal from the PG encoder/gear sensor. The camera’s patrol speed is 1.0 m/min. The patrol range can be set arbitrarily based on the width of the printed material, enabling fixed-point monitoring or automatic reciprocating motion. 2.The entire system is centrally controlled by an Inovance PLC programmable controller. The Inovance touchscreen human-machine interface allows for data setting/modification, operating parameter monitoring/recording, and includes online help, alarm notifications, and historical data logging. The tension control system utilizes closed-loop control with an ultra-light floating roller. The PLC controls the human-machine interface touchscreen for centralized display and settings. It maintains substrate tension during shutdown and automatically stops if the material is cut off. | |

Auxiliary equipment:

| Plate mounting machine ● The rack construction with the wallboard structure after high-strength holistic processing has great working stability and is durable in use ● The 650-line color high-definition camera can reach 70-times amplification ratio, present clear images, possess high resolution ratio, and substantially improve the precision of the plate ● The 19-inch high-resolution liquid crystal display provides clear and bright images and effectively alleviates the visual fatigue of operating workers. ● The maximum width of the equipment is within 2m, the longitudinal length is controlled at 0.7m or so, the height of the equipment is smaller than 1.7m and the drive is on the two sides of the wall-boards of the equipment. The operation, usage, repairing and maintenance are very convenient. Noted:Optional,According to customer needs

Ultrasonic cleaning machine ● Quantity of vibrators: 36 ● Working frequency of the cleanser: 40 KHz ● Total power of electric heater: 3KW ● Temperature control range: 30℃-100℃ ● Ultrasonic power source: 25A/220V ● Heating power source of rinsing tank: 220V 25A Noted:Optional,According to customer needs

Ink viscosity Viscosity control system for an automatic viscosity control of ink with one type of solvent, with a vibration sensorial system. Note: System is designed with interface to connect to Buyer’s supplied fresh solvent/water! Noted:Optional,According to customer needs

AI online detector system ● Real-time defect detection and alarm,Identify various defects, ink defects, overprint errors, dirt spots and foreign objects, text lines, bar-code and QR code defects Early defect detection reduces waste and ensures consistent printing quality Noted:Optional,According to customer needs

Corona treator Additional corona treatment on the material surface to improve ink adhesion Noted:optional -according customer required |

After Sales:

| Factory Environment ● Factory Best Temperature 20-26C ● Factory Best Humidity: 55%-70% ● Environment: well ventilated, No dust ● Standard light

Installation: The seller will send 1 engineer to install, test the production line and train customers’ workers in buyers’ factory. It will take 10 days for whole installation and training. The buyer should cover engineers’ salary, visa cost, Round air tickets, accommodations, transportation in buyers’ country, food, medical care, safety cost, and related cost happens in buyers’ country. Also, the buyer should prepare enough labor, electric wire outside the control panel, Air Compressor and tools for installations. Engineer’s Salary: USD 120 /day, depending on how the engineer makes you satisfied. The date he arrives and leaves shall be counted as paid day.

Warranty: Warranty period for the delivered equipment will be 12 months after completion of erection but not later than 18 months after shipment. The above item does not include the parts, which have regular spares or the parts damaged from normal wear, abnormal operation, improper maintenance and inadequate civil works. The seller is not liable for any production loss under any circumstances. |

Our company

| |

|  |

| |

| Wen zhou Li sheng Printing and Packaging Machinery Co., Ltd. boasts two decades of expertise in providing flexographic printing press solutions. As a reputable manufacturer, our product portfolio encompasses Stack type, Cl type, and Full Servo Sleeve options, tailored to meet the diverse printing requirements of packaging materials such as paper, film, non-woven fabric, and valve woven bags. Our business operations span across the globe, with a steadfast commitment to market orientation, technological innovation, and the delivery of premium-quality products. To this effect, we possess a state-of-the-art factory, where we have invested significantly in the meticulous establishment of Mazak and gantry machining centers. This ensures that each component is meticulously crafted to attain unparalleled precision and guarantee the exceptional quality of our printing presses. | |

More from Honor Series

Explore Other Series