What Are the Solvents Used in Flexo Printing?

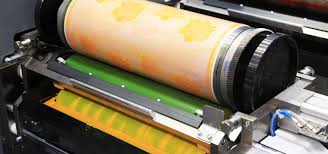

Flexographic printing, often called flexo printing, is widely used in packaging due to its speed and versatility. One of the critical components of this process is the ink, and in particular, the solvents used in the ink formulation. Understanding the solvents used in flexo printing is essential for maintaining print quality, ensuring safety, and optimizing production efficiency.

Common Solvents in Flexo Inks

Solvents in flexographic inks serve to dissolve the resins and adjust the ink’s viscosity and drying speed. The specific choice of solvent depends on the type of substrate, printing conditions, and regulatory requirements. Here are some of the most common solvents used in flexo printing:

-

Ethanol

-

Isopropanol (IPA)

-

Ethyl acetate

-

N-propanol

-

Butyl acetate

-

Water (in water-based inks)

These solvents can be used individually or blended together to create the desired ink properties.

Solvent-Based vs Water-Based Flexo Inks

Flexo printing uses both solvent-based and water-based inks. Solvent-based inks are often preferred for printing on plastic films due to their fast drying time and strong adhesion. Water-based inks are more eco-friendly and commonly used on porous materials such as paper and cardboard.

Role of Solvents in the Drying Process

Solvents in flexo printing inks play a crucial role in drying. Once the ink is transferred to the substrate, the solvent evaporates, leaving behind the pigment and resin. This quick drying capability allows for high-speed printing without smudging or distortion.

Environmental and Safety Considerations

Using solvents also raises environmental and health concerns. Printers must ensure proper ventilation, use solvent recovery systems, and comply with local regulations regarding volatile organic compounds (VOCs). Many companies are transitioning toward low-VOC or water-based alternatives to minimize environmental impact.

Conclusion

Solvents are an integral part of flexo printing inks, especially when working with non-absorbent materials. Choosing the right solvent formulation impacts print quality, drying efficiency, and safety. As the industry evolves, the shift toward sustainable and safer solvent alternatives continues to grow in importance.