Does Flexo Use CMYK?

Flexographic printing is widely used for producing labels, flexible packaging, and corrugated materials. One common question from those new to the process is whether flexo printing uses CMYK. The answer is yes, but with some additional considerations unique to the flexographic method.

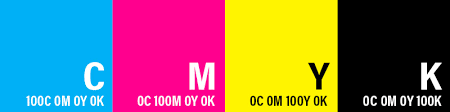

Understanding CMYK in Printing

CMYK stands for Cyan, Magenta, Yellow, and Key (Black). It is the standard color model used in most color printing systems, including digital and offset printing. These four colors can be combined in varying degrees to produce a wide range of full-color images.

How CMYK Is Used in Flexo Printing

Flexo printing commonly uses CMYK for full-color jobs, especially in label and flexible packaging applications. The process involves printing one color at a time using separate printing units. Each unit corresponds to one of the CMYK inks.

Because flexo uses fast-drying inks and high-speed presses, precise registration and consistent ink density are necessary to achieve sharp and accurate color reproduction.

Spot Colors and Extended Gamut

In addition to CMYK, flexo printing often uses spot colors for brand-specific hues or when higher color consistency is required. Some advanced flexo systems also use expanded gamut printing with additional inks such as orange, green, and violet (OGV) to achieve a broader color range beyond standard CMYK.

Challenges and Solutions with CMYK in Flexo

Using CMYK in flexo requires careful management of variables such as:

-

Anilox roll selection and BCM level

-

Plate material and relief depth

-

Substrate absorption and surface treatment

-

Ink formulation and drying systems

Modern flexo presses with automated control systems and high-resolution imaging have made it possible to produce CMYK prints that rival offset and digital quality.

Conclusion

Flexo printing does use CMYK, especially for full-color applications. With the right equipment, materials, and process controls, flexographic printers can achieve excellent CMYK results suitable for a wide range of commercial and industrial packaging needs.