What Is BCM in Flexo Printing?

What Is BCM in Flexo Printing?

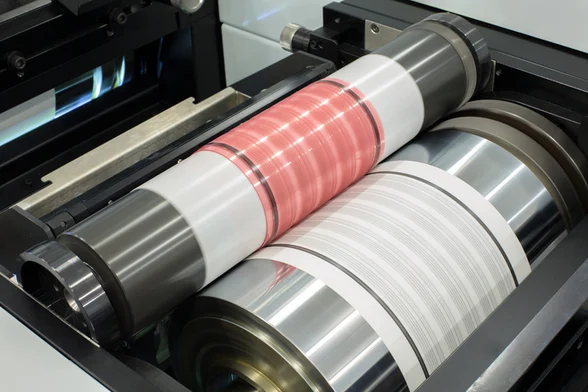

In flexographic printing, achieving consistent and accurate ink transfer is critical to high-quality results. One key concept that helps ensure this consistency is BCM, or Billion Cubic Microns. BCM refers to the volume of ink an anilox roll can carry, and it plays a crucial role in the printing process.

What Does BCM Measure?

BCM stands for Billion Cubic Microns per square inch. It quantifies the amount of ink that can be transferred from the anilox roll to the plate during the printing process. The higher the BCM, the more ink the roll delivers.

Why BCM Matters in Flexo Printing

BCM affects ink density, color strength, and overall print quality. Different printing jobs require different ink volumes:

-

A higher BCM is typically used for white inks or solid areas.

-

A lower BCM is preferred for fine text or halftone images to prevent ink buildup.

Matching the correct BCM level to the print application ensures optimal ink laydown without waste or quality issues.

How BCM Is Determined

The BCM value depends on the engraving pattern and depth of the cells on the anilox roll. Common engraving types include 60°, 30°, and elongated hex patterns. The roll manufacturer usually provides the BCM rating, and printers select rolls based on the requirements of the job.

Monitoring and Maintaining BCM Levels

Over time, ink buildup or wear can alter the effective BCM of an anilox roll. Regular cleaning and inspection help maintain consistent ink volume transfer. Using tools like volume-measuring microscopes ensures accuracy and prevents print defects.

Conclusion

BCM is a vital metric in flexo printing, helping printers control ink flow, improve consistency, and deliver high-quality results. Understanding and managing BCM values allows for greater precision in color and coverage, which is essential in today’s demanding print environment.